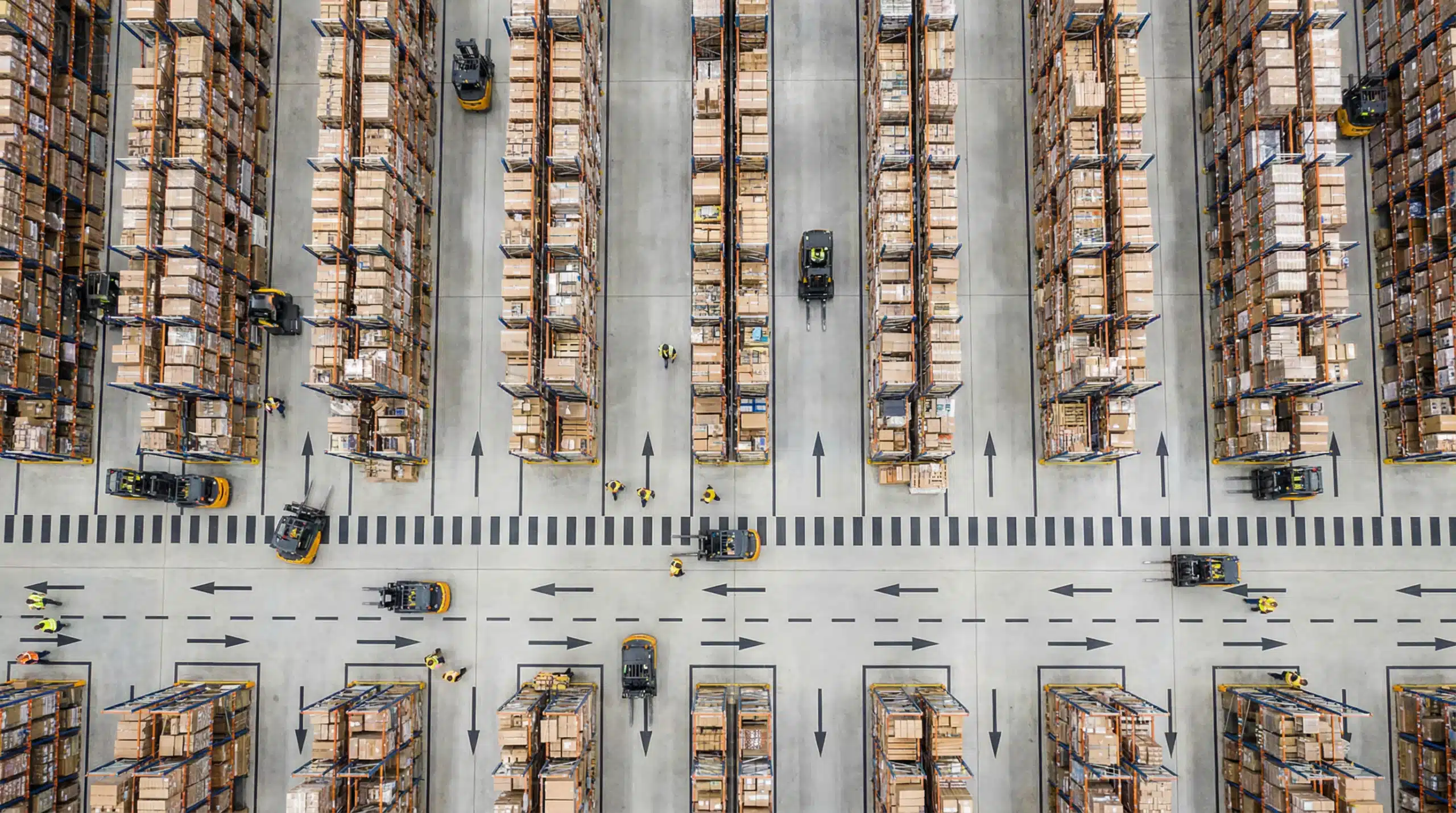

How to Make Your Warehouse Safer For Everyone

Warehouses and loading docks can be dangerous work areas. The potential of accidents involving forklifts or falls require continued vigilance plus updates on safety standards whenever necessary.

To protect falls, the Occupational Safety and Health Administration (OSHA) requires protection for employees such as guardrails, toe-boards, and protective equipment like safety gates. They have good reason for the standards: the agency reports that falls account for 20 percent of all fatal (345 annually) and lost-work-day injuries (202,066 annually). The establishment of guardrail, safety net, or personal fall arrest systems protect workers who operate at least four feet above a lower level. The changes prevent 29 deaths and nearly 6,000 lost-work-day injuries every year.

What areas of the warehouse are most vulnerable to accidents and what can be done to make sure they don’t happen? Here are a few warehouse safety tips:

Multi-level rack picking systems. These modules that handle order fulfillment are typically constructed using a metal support structure involving handrails, landings, and stairways. Products stored in racks are picked to conveyors and other transportation systems. The problem is, these work areas are often very small and contained within the rack system. Typical mezzanine barriers do not fit, so special barriers are needed to configure to these systems.

Vacant docks. Open dock doors that are not adequately protected can be extremely dangerous. To mitigate the danger, facilities need to install barriers near the edge of the dock door. These barriers need to have an element of resistance so they can stretch across wide openings and stop up to 30,000 pounds with minimal damage.

Plant floors. Racks, powered vehicles, and workers on foot can increase the potential of a collision. While overhead walkways are ideal to separate people from vehicles, they are not always practical. The best way is to incorporate floor marking and safety signs that control movement. The proper signage and markings can signal speed limits, right of way standards, procedures for drivers who need to remain their vehicle during loading or unloading. The warehouse can also establish separate doors for pedestrians and vehicles, restricted areas, and special areas for storing hazardous materials.

Elevated platforms. These present the most common areas where falls are likely. According to OSHA standards, all must have handrails and gates around the edges. When gates are opened for loading and unloading, companies need to ensure there are no exposed areas where workers can fall. One way to make this happen are dual reciprocating barriers. These create a controlled access area that prevents the inner and outer gates from opening at the same time. For example, the best models ensure both gates work at the same time: When the outer gate opens to allow pallets in, the inner gates automatically closes to keep workers out. Some designs include a raised toe board to prevent materials from falling over the elevated edge, or they include a safety latch for the outer gate that only works when workers stand outside the work zone, which prevents it from being raised accidentally from workers located inside the work zone.

Being smart about safety is not only required, but it will help defray costs in the long run. What type of safety training does your company employ? Has your warehouse operation improved over time when it comes to safety?

Smarter Warehouse Management Starts Here

Cadre WMS delivers real-time visibility, automated workflows, and seamless ERP integration for warehouses of every size.

Request a Demo

Frequently Asked Questions

What are the most common OSHA violations in warehouse facilities?

The most frequent OSHA violations in warehouses include inadequate fall protection systems, improper forklift operation procedures, insufficient personal protective equipment usage, blocked emergency exits, and lack of proper hazard communication training. Fall protection violations are particularly common since OSHA requires guardrails and safety systems for any work area four feet or higher above ground level.

How often should warehouse safety equipment be inspected and maintained?

Safety equipment should be inspected daily for critical items like forklifts and fall protection gear, while comprehensive inspections should occur monthly or quarterly depending on usage. OSHA requires regular documentation of these inspections. Safety barriers, guardrails, and dock equipment need immediate attention if damaged, as compromised equipment can lead to serious accidents and regulatory violations.

What safety training is required for new warehouse employees?

New warehouse workers must complete general safety orientation covering emergency procedures, personal protective equipment use, and hazard recognition. Additionally, they need job-specific training for equipment operation, fall protection systems, and material handling procedures. OSHA mandates that employees receive training before starting work and periodic refresher courses to maintain safety certifications and awareness.

How much does implementing comprehensive warehouse safety measures typically cost?

Initial safety implementation costs range from $10,000 to $50,000 for average-sized warehouses, depending on facility size and required equipment. This includes guardrails, safety gates, floor markings, and protective barriers. However, these investments typically pay for themselves within 2-3 years through reduced insurance premiums, fewer worker compensation claims, and decreased OSHA fines.

What should I do immediately after a warehouse safety incident occurs?

First, ensure the injured person receives immediate medical attention and secure the accident scene to prevent further incidents. Document everything with photos and witness statements, then report the incident to OSHA within required timeframes (8 hours for fatalities, 24 hours for hospitalizations). Conduct a thorough investigation to identify root causes and implement corrective measures to prevent recurrence.