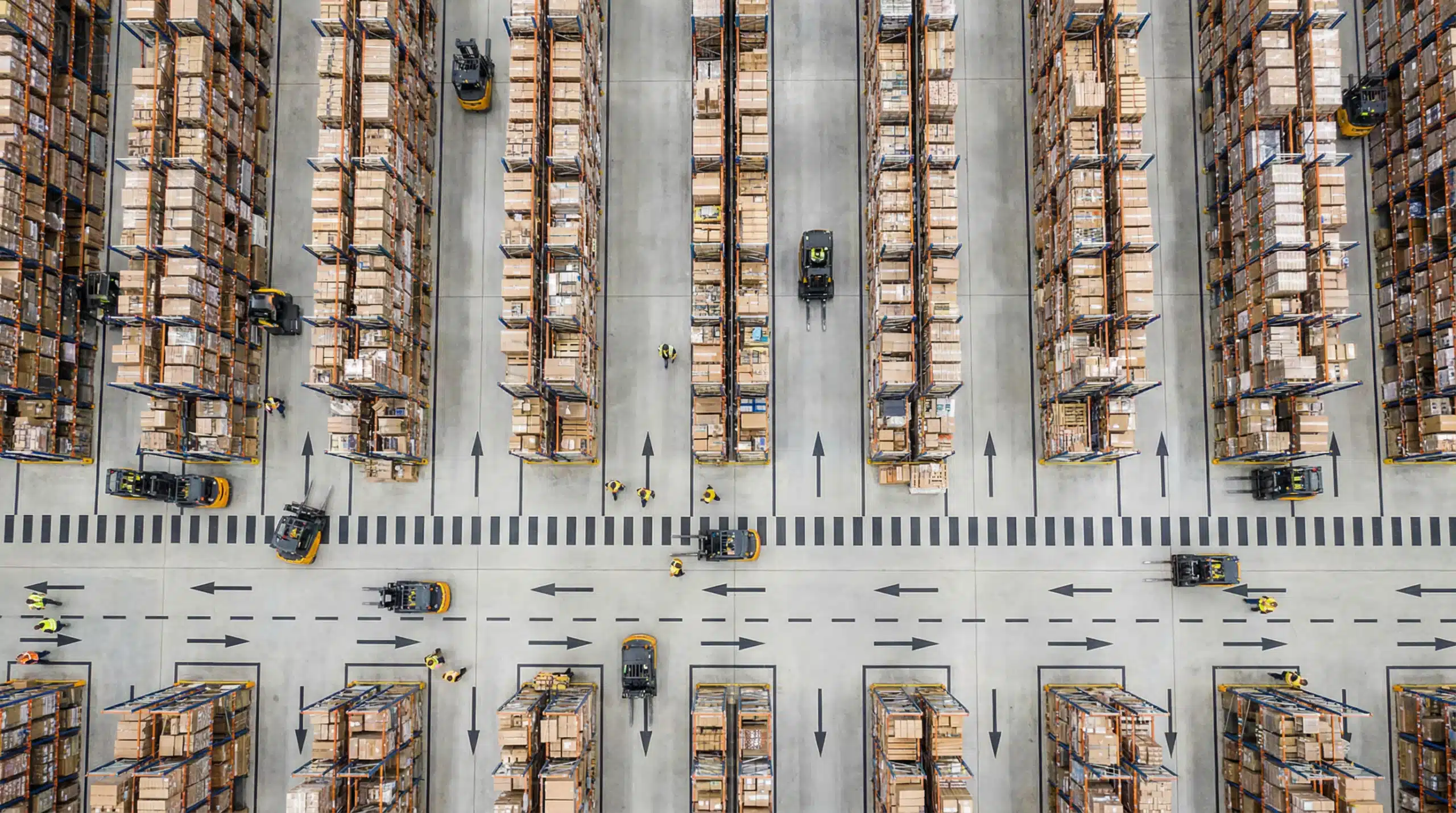

Is Supply Chain Management Dead? Or is it Changing (Forever)?

Since the advent of the assembly line, supply chain management has been an important factor when it comes to success. While there has always been a need for access to real-time data, increasingly, legacy technology limitations are resulting in a flawed system with at-best, limited transparency that means keeping up with data-driven competitors is nearly impossible.

But soon, that may all be a thing of the past. Technology is moving toward all-things-digital at warp speed, and the potential for an automated system that’s ready and willing to take over the supply chain management industry entirely is just as quickly disrupting traditional ways of working.

Some in the industry think it will only be a few more years until the supply chain function could be entirely obsolete. Instead, they say it will be replaced by a self-regulating robotic utility that manages work flows end-to-end while needing little to no human interaction.

It begs the questions: Could this be possible? And more importantly, would it be better?

Imagining the Supply Chain of the Future

We can see some pros to a totally automated supply chain. A highly-functioning digital foundation means companies may be able to gain real-time, high quality data in a snap. Virtually instantaneously, data could be:

- Captured

- Analyzed

- Integrated

- Accessed

- Interpreted

All for the benefit of a more smoothly running, completely enhanced version of the supply chain industry across the board.

So, is this likely? Could the future of the supply chain really be fueled by AI, automation, predictive analytics and robotics?

The trend of tech replacing people isn’t just a suspect for our industry – it’s becoming a reality across hundreds of industries, on a global scale, so it doesn’t seem all that far-fetched to imagine a future where AI and automated processes allow for advanced analytics, robotics and more.

And so, if we do see a shift to an increasingly automated industry, where will that leave supply chain professionals?

Will those higher up in supply chain organizations need to refocus? Move away from managing people? Will those who analyze data and use algorithms to make effective forecasts become increasingly in demand? And beyond this, what types of supply chain challenges in the future should we expect?

Right now there seems to be more questions than answers about the future of supply chains – but like with any shift in industry, those who continue to keep up and remain agile, learning new skills and adapting to new needs, will be the ones who are here even if the trend continues and the whole world of supply chain does indeed change.

Contact the experts at Cadre Technologies to help automate and streamline your warehouse operations with a new WMS!

End-to-End Supply Chain Visibility

Connect demand planning, inventory control, and transportation management with Cadre's integrated platform.

Request a Demo

Frequently Asked Questions

What skills will supply chain professionals need in an automated future?

Supply chain professionals will need to develop technical skills in data analytics, AI system management, and predictive modeling. Understanding how to interpret automated insights, troubleshoot digital systems, and make strategic decisions based on AI-generated recommendations will become essential. Professionals should also focus on developing skills that complement automation rather than compete with it.

How long will it take for full automation to replace traditional supply chains?

Industry experts suggest it could be just a few years before significant automation takes hold, though complete replacement of human involvement may take longer. The timeline depends on factors like technology adoption rates, regulatory requirements, and industry-specific challenges. Companies are already implementing partial automation, with full transformation likely occurring gradually over the next decade.

What are the main risks of implementing fully automated supply chain systems?

Key risks include system failures that could halt entire operations, cybersecurity vulnerabilities, loss of human oversight for complex decisions, and high initial implementation costs. Over-reliance on technology without human backup plans can create single points of failure. Additionally, automated systems may struggle with unexpected disruptions that require creative problem-solving and adaptability.

How can companies prepare their current supply chain for digital transformation?

Companies should start by upgrading legacy systems, investing in data infrastructure, and training employees on new technologies. Implementing cloud-based solutions, establishing data governance protocols, and creating change management strategies are crucial first steps. Partnering with technology providers and conducting pilot programs can help organizations transition smoothly while minimizing operational disruptions.

What types of supply chain roles will remain human-centered despite automation?

Strategic planning, vendor relationship management, crisis response, and creative problem-solving roles will likely remain human-centered. Positions requiring emotional intelligence, complex negotiations, and ethical decision-making cannot be easily automated. Additionally, roles focused on system oversight, exception handling, and cross-functional collaboration will continue to require human expertise and judgment.