RFID vs NFC: Comparing Two Warehouse Management Technologies

In the world of warehouse management technology, two key terms often come to the forefront – Radio Frequency Identification (RFID) and Near Field Communication (NFC). Both technologies use radio waves to facilitate wireless communication, but they serve diverse purposes. After covering the nuances of Radio Frequency (RF) and RFID in a previous article, now we’ll explore the subtle differences between RFID and NFC. We’ll examine their practical applications and assess their increasingly important roles in the rapidly evolving landscape of warehouse management

RFID and NFC: A Technological Overview of Radio Frequency Identification and Near Field Communication

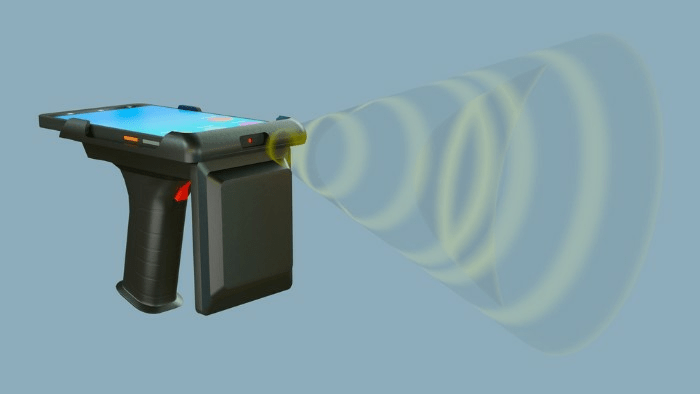

What is RFID? An RFID system comprises two main components – an RFID reader and an RFID tag, and it is a wireless technology that utilizes radio waves to read and capture data stored on a tag attached to an object. Each RFID tag has a unique identifying feature that can be read from a distance without line-of-sight, thus providing an efficient means of asset tracking and inventory management.

RFID operates in different frequency ranges, including low frequency (LF, 125 – 134 kHz), high frequency (HF, 13.56 MHz), and ultra-high frequency (UHF, 856 – 960 MHz). The operating frequency impacts the read range, read speed, and ability to read through materials.

When it comes to RFID tags, there are two different types – passive and active. Passive RFID tags don’t have their own power source; instead, they receive power from the reader’s electromagnetic fields. On the contrary, active RFID tags are equipped with their own power source, like a battery, enabling them to broadcast radio waves to the RFID reader.

NFC, on the other hand, is a subset of high-frequency (HF) RFID that operates at the same frequency of 13.56 MHz. NFC is often embedded in consumer devices like NFC-enabled smartphones. NFC allows for two-way communication, making it possible for NFC devices to act as both a reader and a tag. This feature enables peer-to-peer communication, like contactless payment or card emulation, making NFC an integral part of secure communication.

Understanding RFID Technology: RFID Tags in Detail

RFID tags, as the workhorses of any RFID system, are responsible for the seamless and efficient tracking and identification of items in a warehouse. While we understand that these tags can be broadly categorized into passive and active types, let’s dive deeper into their practical implications, benefits, and potential challenges in a warehouse setting.

Passive RFID Tags

These tags are generally smaller and less expensive to produce, making them suitable for tracking large volumes of relatively inexpensive items. Due to their lack of an internal power source, their operational life is virtually limitless, unless physically damaged. However, their read range is dependent on the power of the RFID reader’s electromagnetic field, which may limit their effectiveness in large-scale warehouse environments. It’s important to consider these factors when implementing a passive RFID system in your operations.

Active RFID Tags

Equipped with their own power source, active RFID tags can broadcast their signals over a much larger range, making them excellent for monitoring high-value goods or large assets. They can even be integrated with sensors to monitor parameters like temperature or humidity, providing additional valuable data for certain goods. The trade-off, however, is their higher cost and limited operational life due to battery depletion. Balancing these benefits and constraints is key when choosing to employ active RFID tags in your warehouse.

Understanding the specifics of each type of RFID tag, their potential applications, and limitations will enable you to make informed decisions when designing and optimizing your warehouse management systems.

NFC Tags: Powerhouses of Short-Range Communication

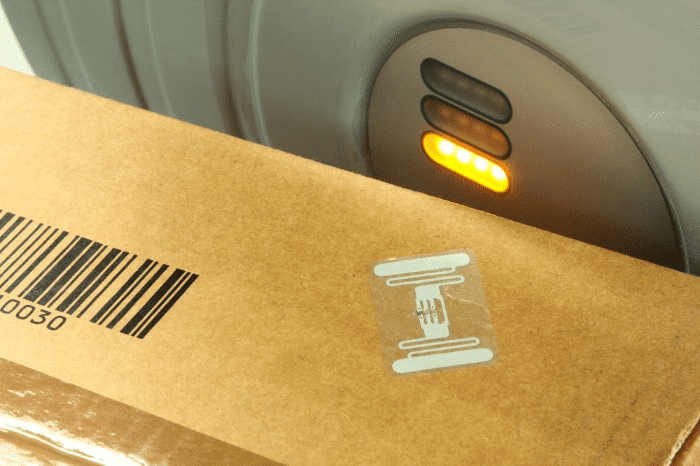

NFC tags differ from RFID tags in several significant ways that offer unique benefits within a warehouse environment. One key difference is their ability to facilitate two-way communication, unlike RFID’s more common one-way communication. This enables data exchange between devices, presenting opportunities for real-time updates and responsive asset tracking.

For instance, warehouse operators can tap an NFC-enabled device to a tagged item to immediately pull up relevant information about that product or component. This could range from stock levels and shipment data to maintenance records, all instantly accessible at the point of interaction.

Moreover, NFC technology allows devices to function as both readers and tags, leading to versatile applications within a smart warehouse. Whether it’s expediting device pairing for data sharing, or conducting rapid, contactless transactions at the point of sale, NFC helps streamline operations, minimize errors, and improve overall warehouse productivity.

As the industrial Internet of Things (IoT) continues to evolve, the adoption of NFC technology in warehouse management is expected to rise, given its capacity to enhance system integration and efficiency.

Key Differences Between RFID and NFC:

When comparing RFID and NFC technologies, several key differences are notable:

- Range: RFID technology, particularly in its high-frequency variations, can offer a significant range of over 100 feet. This capability enables effective scanning of multiple RFID tags simultaneously, which can greatly expedite processes such as inventory management. NFC, conversely, is a short-range communication technology, operating effectively within a close proximity of about 4 cm.

- Frequency: RFID operates at a variety of frequencies, which include: (LF) Low Frequency: 125-135 KHz, (HF) High Frequency: 13.56 MHz, (UHF) Ultra-High Frequency: 868-930 MHz, and Microwave Frequencies: 2.45 GHz and 5.8 GHz. Each of these has unique characteristics. NFC, being a subset of HF RFID, operates specifically at 13.56 MHz.

- Power Source: RFID tags can either be passive, drawing power from the reader’s signal, or active, possessing their own power source. In contrast, NFC tags are always passive.

- Security: NFC’s short range can provide an enhanced level of security against potential eavesdropping. This makes it a preferred choice for applications that require secure access control and contactless payments.

- Interactivity: Unlike most RFID systems, NFC can facilitate peer-to-peer communication, enabling two NFC devices to exchange data directly.

- Cost: Typically, RFID tags can be more cost-effective than NFC tags, though costs can vary based on factors such as volume, type, and specific use cases.

While both technologies provide unique advantages, understanding their differences can help businesses make informed decisions on which technology to implement based on their specific needs and operational requirements.

The Role of RFID in Warehouse Management:

RFID devices, including the RFID reader and tags, have significantly improved the efficiency of warehouse operations. Their ability to read multiple tags simultaneously has revolutionized inventory tracking and asset location management. An RFID system provides real-time updates of asset location and quantity, thereby improving visibility and reducing time spent on manual inventory checks.

Moreover, RFID tags, particularly active RFID tags, can store data regarding the asset they are tagged to, like its manufacturing date, expiration date, batch number, and more. This feature aids in maintaining the quality and authenticity of goods, particularly important in industries like pharmaceuticals and food and beverage.

Exploring NFC in Warehouse Management:

An NFC device, such as an NFC-enabled smartphone or identification badge, carries immense potential in warehouse management. These devices can be passive: only communicating when a reader is nearby, or active: able to initiate communication with other devices.

The secure two-way communication offered by NFC, particularly with active NFC devices, has been leveraged in access control, with NFC devices used to access restricted areas, thus enhancing security within warehouses.

Moreover, active NFC devices offer added benefits such as the ability to initiate secure connections for data transfer, adding an extra layer of convenience and flexibility in a warehouse environment.

NFC devices can also facilitate faster pairing of devices in a warehouse environment, eliminating the need for manual configurations. For instance, an NFC-enabled device can be paired with an NFC reader with just a tap, thereby saving time and reducing errors.

RFID vs NFC: Is a Choice Required?

In an industry where efficiency and accuracy are paramount, choosing the right technology has a direct impact on operational performance. Therefore, the decision between RFID and NFC largely depends on the specific needs of a warehouse.

If your operations demand reading multiple tags at a distance for efficient inventory management, RFID stands as a reliable technology. On the other hand, if your warehouse operations require secure, short-range, two-way communication for tasks like access control or device pairing, NFC might be a more suitable choice for that application.

However, given the complementary strengths of RFID and NFC technology, many warehouse operators opt for a hybrid approach. This approach involves using RFID for operations requiring a long read range and multiple tag reading, and NFC for operations needing secure, close-range, two-way communication. By taking advantage of both technologies, operators can create an optimal system that meets the needs of their warehouse and helps them reach their goals.

Challenges and Limitations of RFID and NFC Technologies:

While RFID and NFC technologies bring a host of benefits to warehouse management, they are not without their challenges. For instance, the initial investment required for RFID systems can be substantial, particularly for active RFID tags and readers.

NFC, although generally less costly, may face interoperability issues across different device manufacturers. Moreover, both technologies can be affected by environmental conditions; for example, metal or liquids can interfere with radio frequency signals, potentially leading to inaccuracies in tag reading.

Future Trends in RFID and NFC Technologies:

As RFID and NFC technologies continue to evolve, we can expect to see significant advancements that could further revolutionize warehouse management. Advancements in memory chip capacities and operating frequency ranges promise to enhance the data storage capabilities and read ranges of RFID and NFC tags, paving the way for more precise asset management. Furthermore, the increasing integration of these technologies with Internet of Things (IoT) devices may allow for more comprehensive and automated warehouse management solutions.

Conclusion:

In the ever-evolving landscape of warehouse management technology, understanding the distinctive functionalities of RFID and NFC becomes pivotal. With RFID’s effectiveness in long-range, one-way communication, it’s a powerful tool for asset tracking and inventory management. Conversely, NFC excels in scenarios that call for secure, short-range, two-way communication, making it perfect for secure access control and device pairing. Recognizing and capitalizing on these differences, many warehouse operators already adopt a hybrid approach, harnessing the strengths of both RFID and NFC.

However, the right technology is only part of the equation. To truly unlock efficiency and security, you need a robust warehouse management system. Cadre Technologies offers innovative Warehouse Management Systems (WMS) that seamlessly integrate with RFID, NFC, and other essential technologies. With our comprehensive software solutions, you can leverage these powerful technologies to their fullest, driving operational efficiency, accuracy, and security to new heights.

To learn more about RFID and NFC technologies, or to explore our WMS solutions, contact Cadre Technologies today. Our team of experts is ready to help you optimize your warehouse operations.

FAQ

How Secure Are RFID and NFC Technologies?

RFID and NFC technologies offer robust security features. While RFID tags primarily function through one-way communication, they often include security mechanisms such as data encryption or password protection. NFC, on the other hand, excels in secure two-way communication, making it an ideal choice for tasks requiring data exchange or secure access control. However, like any wireless technology, these systems are not immune to security threats and should be used with proper protective measures.

What Types of Objects Can RFID and NFC Tags Be Attached To?

RFID and NFC tags can be attached to a wide variety of items. This includes virtually any product in a warehouse, from small consumer goods to large industrial equipment. However, care should be taken when attaching these tags to metal objects or items containing liquid, as these materials can interfere with radio frequency signals.

Can RFID and NFC Technologies Be Integrated with Other Warehouse Management Systems?

Absolutely. RFID and NFC technologies are often integrated with Warehouse Management Systems (WMS) to provide comprehensive tracking and management solutions. Integration with WMS enables real-time updates of inventory levels, streamlined workflows, and improved decision-making processes.

RFID vs NFC: Which is Better for My Operations?

Choosing between RFID vs. NFC largely depends on the specific needs of your operations. If your operation requires reading multiple tags at a distance for efficient inventory management, RFID could be the more suitable technology. On the other hand, if your operation requires secure, short-range, two-way communication, such as for access control or device pairing, NFC might be a better choice.

Remember, the RFID and NFC technologies are not mutually exclusive. Many operations benefit from a hybrid approach that leverages the strengths of both technologies.