How Amazon Disrupted the Supply Chain Model and How Your Business Can Adapt

Reading Time: 4 minutes

In less than three decades, Amazon has forever altered the landscape of retail. This change has been powered by its unique Amazon supply chain model, which is designed for efficiency and speed. Its growth has been phenomenal, and according to analysts, Amazon is projected to exceed a yearly revenue of $1 trillion by 2027.

The secret to Amazon’s meteoric rise lies in its mastery of supply chain management. By leveraging a complex network of warehouses, advanced data analytics, and multi-tier inventory technology, Amazon has established itself as a dependable marketplace for nearly any product or service one can think of.

Moreover, through Amazon Prime and its innovative promise of two-day delivery, the company has redefined speed as its brand disrupted the traditional supply chain model. Here are elements of Amazon’s approach that other companies can adopt to bolster their success:

Utilize a Combination of Outsourced Inventory Management and Insourced Logistics

A key facet of the Amazon logistics model is its effective combination of outsourced and insourced elements. A prime example of Amazon outsourcing supply chain responsibilities is its dependence on third-party sellers to supply niche inventory that doesn’t require storage in regular Amazon warehouses. Despite this outsourced aspect, Amazon takes control of its logistics internally. Employing its proprietary delivery platforms to fulfill orders, Amazon ensures delivery promises are met, thereby accelerating a process that could potentially lag if entirely dependent on third parties for shipping and delivery.

Provide Customers with Varied Delivery Options

Amazon Prime offers a plethora of delivery options, from same-day to three to five days. By promising and delivering the kind of delivery customers want, Amazon has effectively positioned itself as the go-to option in the world of e-commerce.

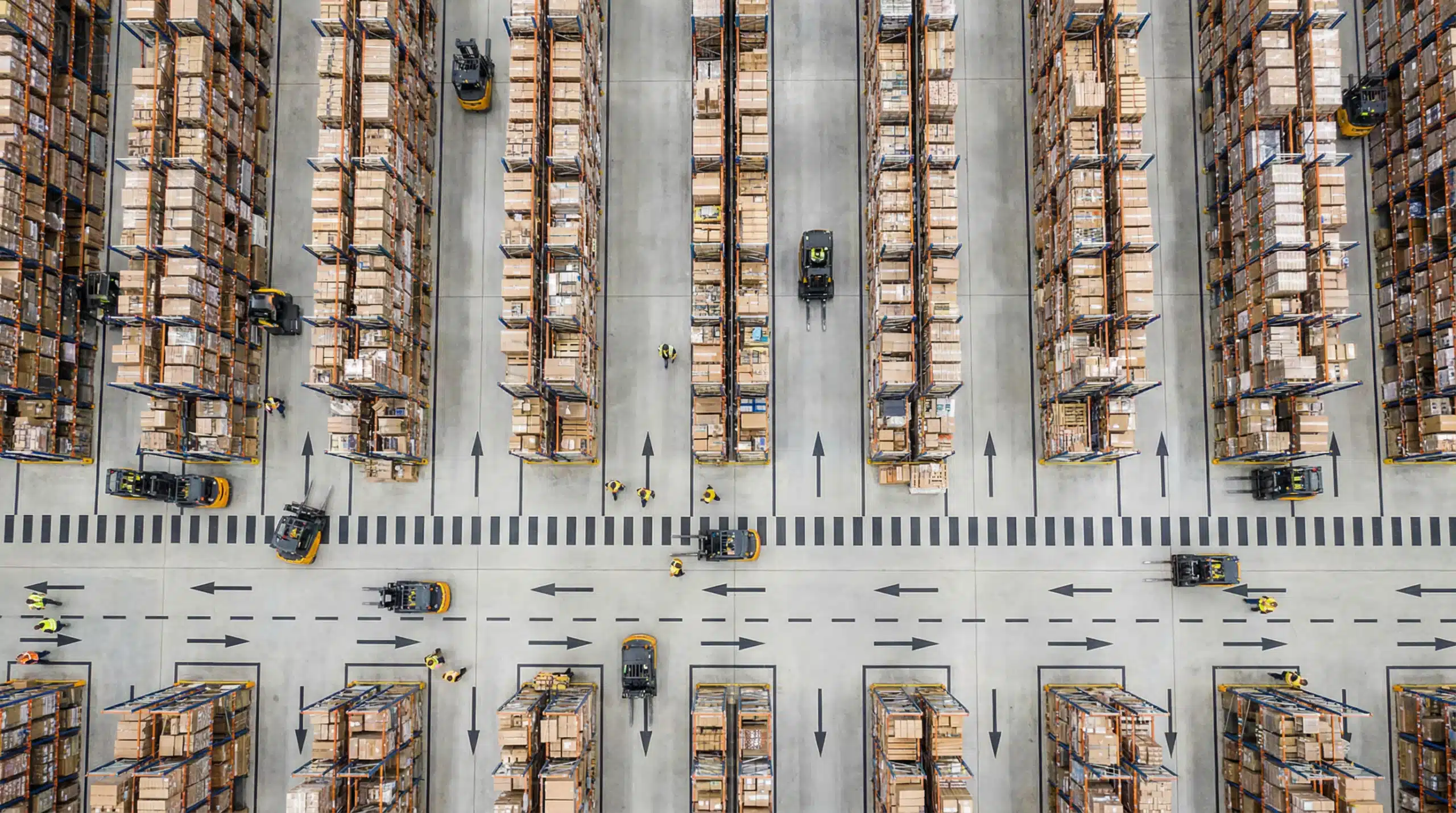

Establish a Variety of Warehouses

Amazon operates a network of over 385 fulfillment centers across the U.S., staffed by hundreds of thousands of employees. These centers are strategically located near urban areas, ensuring that inventory is nearby even before orders are placed. The company also categorizes its storage spaces according to various needs: prime storage for books and magazines, pallet prime for high-demand full case products, and specialized storage for high-demand products, irregularly shaped low-demand products, and small items.

Integrate Automation

Amazon was among the first to integrate automated solutions into its warehouses. In 2012, it began using robots in its fulfillment centers and, as of 2022, employs over 520,000 robots worldwide. These robots pick, pack, and sort items without human assistance, significantly increasing efficiency.

Fulfill Orders Immediately

Amazon has redefined what speed means in order fulfillment by eliminating cut-off times or batch processing. It has developed a routine of continuous processing and pick-ups to ensure no time is wasted at the customer’s expense.

Since its inception, Amazon has continually innovated and redefined the supply chain. With developments in autonomous vehicles, warehouse drones, and other emerging technologies, the company is poised for even more disruptive innovation.

While most companies may not have the scale or budget to match Amazon’s efforts, they can implement similar strategies to improve their processes. In the era of Amazon, customers crave this level of insight and immediate gratification – in fact, they demand it.

How Cadre Technologies Can Help

Understanding Amazon’s strategies and the ways it has disrupted the supply chain model is a good starting point, but to stay competitive, it’s crucial to tailor these insights to your own operations. That’s where about cadre technologies comes in.

Cadre Technologies offers industry-leading software solutions that can help your business enhance its supply chain efficiency and exceed customer expectations. Whether it’s our warehouse management system, 3PL logistics software, or delivery solutions, our products can provide the tools you need to streamline your operations and deliver exceptional service.

Don’t wait to transform your supply chain management. Contact our team of experts today to find out how we can help you adapt to the rapidly changing supply chain management landscape and succeed in an Amazon-dominated world.

Frequently Asked Questions

What is the biggest mistake companies make when trying to copy Amazon’s supply chain model?

The biggest mistake is attempting to replicate Amazon’s entire system without considering scale and budget constraints. Companies often try to implement all strategies simultaneously rather than prioritizing based on their specific needs and resources. A more effective approach involves selecting key elements like automation or varied delivery options that align with your business size and gradually scaling up operations.

How much does it typically cost to implement warehouse automation like Amazon uses?

Warehouse automation costs vary significantly based on scope and complexity, ranging from $50,000 for basic systems to millions for comprehensive robotics solutions. Small to medium businesses can start with affordable automated sorting systems or inventory management software before investing in robotic picking systems. The key is to calculate ROI based on labor savings and efficiency gains rather than trying to match Amazon’s $775 billion robot investment.

Why do customers now expect Amazon-level delivery speeds from all retailers?

Amazon has fundamentally shifted customer expectations by making fast delivery the new standard rather than a premium service. Through Amazon Prime’s two-day delivery promise, customers now view speed as a basic requirement, not a luxury. This psychological shift means businesses that can’t offer competitive delivery times risk losing customers who have been conditioned to expect immediate gratification in their shopping experience.

When should a small business consider outsourcing vs insourcing their logistics operations?

Small businesses should consider outsourcing logistics when order volumes exceed their capacity to maintain quality and speed, typically around 100-500 orders per day. Insourcing makes sense when you need greater control over customer experience or have specialized products requiring careful handling. The decision point usually comes when outsourcing costs become less than the combined expenses of warehouse space, staff, and technology investments.

What are the benefits of having multiple warehouse locations like Amazon?

Multiple warehouse locations reduce shipping distances, enabling faster delivery times and lower transportation costs. They also provide inventory redundancy, ensuring product availability even during regional disruptions or high-demand periods. Additionally, distributed warehouses allow for better inventory positioning based on regional demand patterns, reducing stockouts and improving customer satisfaction while optimizing storage and fulfillment costs across different markets.