Warehouse Manager Job Description & Responsibilities

Warehouse managers are the backbone of efficient logistics. Discover what it takes to excel in this role and the tools that can transform your operations.

A warehouse manager oversees daily warehouse operations, ensuring efficiency and safety. They manage inventory, coordinate shipping and receiving, and lead warehouse staff. This role requires a mix of strategic planning and hands-on management. Read on to learn about their key responsibilities, required skills, and tools they use.

Key Takeaways

- Warehouse managers play a crucial role in operations by managing inventory, staff, and safety protocols to ensure efficiency and compliance.

- Strong organizational, communication, and problem-solving skills are essential for warehouse managers to lead their teams and streamline processes effectively.

- Opportunities for career advancement in warehousing exist, with potential roles such as logistics director, especially for those with relevant education and experience.

Understanding the Role of a Warehouse Manager

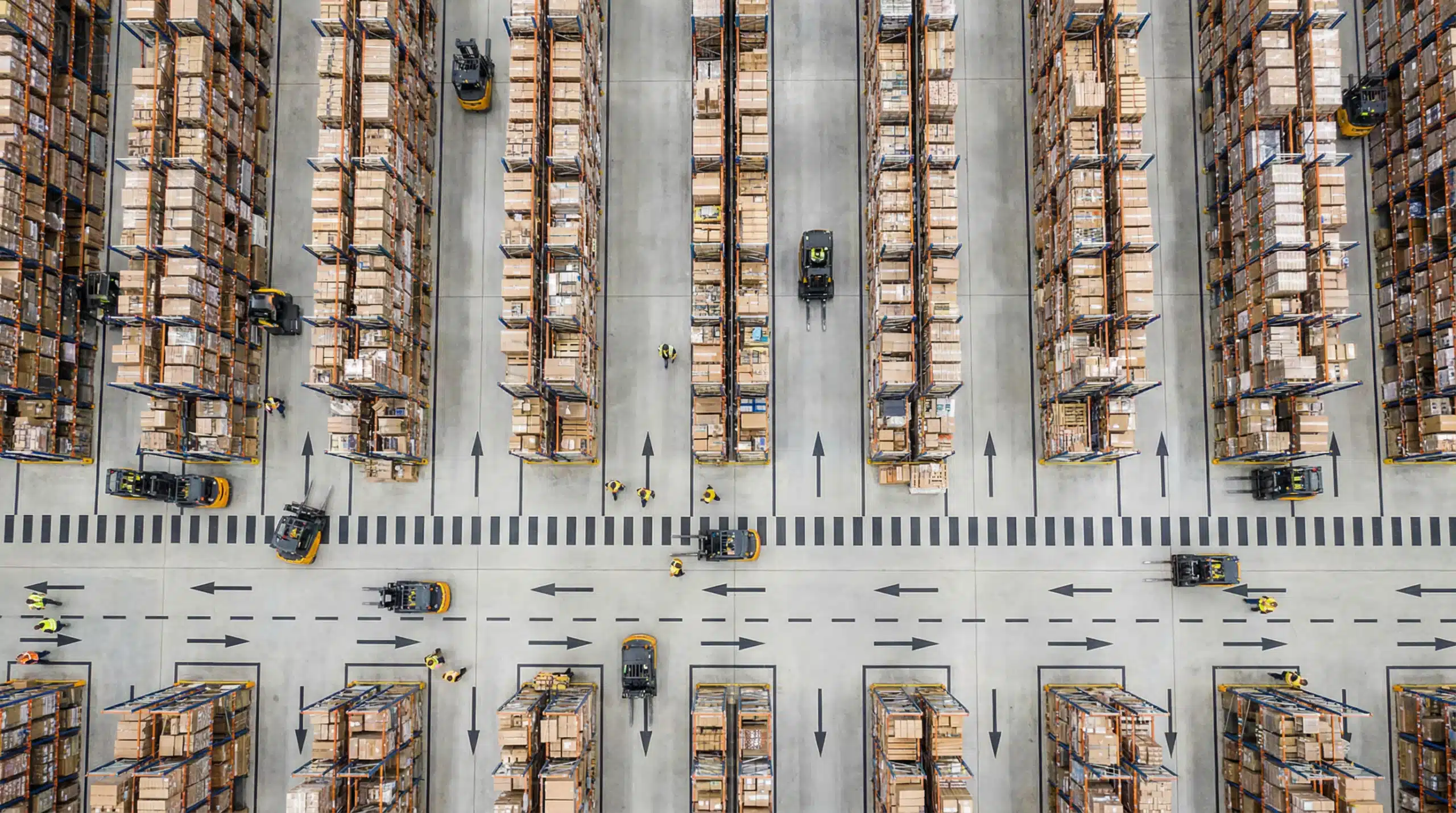

The warehouse manager is the head of warehouse operations, ensuring that day-to-day activities align with quality standards and operational efficiency. They are responsible for overseeing the entire logistics process, from managing inventory levels to coordinating shipping and receiving processes. A well-organized and efficient warehouse ensures products are available when and where they are needed, highlighting the manager’s crucial role in the supply chain.

A significant part of their job involves enforcing safety protocols to protect warehouse staff and comply with legal requirements. This role requires a blend of strategic planning and hands-on management, making it a challenging yet rewarding position.

Here are the key responsibilities and skills required to excel in this role.

Key Responsibilities of a Warehouse Manager

A warehouse manager’s job description consists of diverse responsibilities. They:

- manage inventory levels

- organize storage

- oversee shipping and receiving

- implement safety protocols

- ensure timely deliveries

- manage warehouse staff

A closer look at these responsibilities reveals what makes a successful warehouse manager.

Managing Inventory Levels

Effective inventory control is at the heart of warehouse management. Warehouse managers utilize advanced inventory tracking systems to monitor stock levels and manage deliveries efficiently. Inaccurate inventory data can lead to significant operational inefficiencies, making it difficult for warehouse staff to locate products and manage stock accurately. That’s why maintaining precise inventory records is essential for meeting customer demand and ensuring timely order fulfillment.

Warehouse managers must also address challenges such as seasonal demand fluctuations and inventory shortages. Quickly assessing problems and implementing practical solutions helps maintain a balance between inventory levels and customer demand. Additionally, adopting smart warehouse technologies and automation enhances efficiency and precision in these warehouse processes.

Overseeing Warehouse Staff

Leading a warehouse team requires strong leadership and communication skills. Warehouse managers are responsible for supervising and training staff to ensure optimal operations while meeting productivity and quality standards. They act as team leaders, assigning tasks, preparing workflows, and determining staffing requirements to enhance productivity and quality.

Pro tip: Clear communication ensures that all team members understand their roles and responsibilities, fostering effective collaboration across departments. A warehouse manager’s ability to motivate and manage staff is key to maintaining a cohesive and high-performing team.

Implementing Safety Protocols

Safety is a paramount concern in warehouses. Warehouse managers are tasked with establishing and enforcing safety standards to protect employees and ensure compliance with legal requirements. Minimizing workplace hazards through stringent safety protocols creates a secure working environment, essential for maintaining productivity and employee morale.

Essential Skills for Warehouse Managers

A successful warehouse manager must possess a blend of organizational skills, problem-solving abilities, and effective communication. These skills are integral to managing inventory, leading staff, and ensuring smooth warehouse operations.

These critical skills deserve a closer look.

Organizational Skills

Maintaining inventory accuracy, crucial for fulfilling orders promptly and correctly, relies on strong organizational skills. Warehouse managers are responsible for scheduling and directing the warehouse team to optimize operational efficiency. Using mobile devices or computer terminals for product logging and scheduling ensures meticulous planning and execution in warehouse operations.

These skills also involve managing inventory records accurately to meet demand without causing overstocking or stockouts. Effective organizational skills enable warehouse managers to create a structured and efficient working environment.

Problem-Solving Skills

Quickly resolving issues is crucial for maintaining operational efficiency and preventing disruptions. Warehouse managers must evaluate staff performance, address personnel issues, and implement solutions to unexpected challenges. Problem-solving skills ensure smooth warehouse operations despite any arising hiccups.

Communication Skills

Effective communication directly impacts both performance and safety in warehouse roles. Warehouse managers must coordinate with various stakeholders, including warehouse staff, other departments, and external partners, to ensure that everyone is on the same page. Clear communication aids in meeting deadlines, maintaining quality, and delivering excellent service to customers and clients.

Required Education and Certifications for Warehouse Managers

Many employers prefer candidates with a bachelor’s degree in business, logistics, or a related field. However, some positions may accept an associate degree combined with relevant work experience as an adequate qualification. Professional certifications, such as the Certified Supply Chain Professional (CSCP), can enhance job prospects for aspiring warehouse managers.

A successful warehouse manager needs a combination of technical expertise, leadership qualities, and soft skills to oversee operations effectively. Skills in technology integration and automation can lead to roles in systems management or IT within logistics. Specializing in areas like inventory control or safety compliance may open niche career paths in those specific fields.

Salary Expectations for Warehouse Managers

According to Salary.com, the average salary for a warehouse manager in the U.S. is approximately $96,498, with variations between $82,659 and $112,975 depending on factors like geographical location and warehouse size. For instance, salaries in San Francisco, CA, can exceed the national average by 25%. Larger facilities generally offer higher compensation due to the increased scope and complexity of operations.

Performance-based incentives, in addition to base salary, can significantly affect total compensation. Experience and educational background significantly influence salary, with advanced degrees or certifications often leading to higher pay.

Technology and Tools Used by Warehouse Managers

Technology plays a crucial role in modern warehouse management. Warehouse managers leverage advanced tools and software, including warehouse equipment, to streamline operations, track inventory levels, and optimize order fulfillment. These technologies enhance productivity and reduce operational costs.

Here are some key tools in detail.

Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) streamlines inventory management and order fulfillment processes. It provides real-time visibility into inventory and order status, directing resources efficiently to ensure smooth and effective operations. A WMS integrates with various systems, managing inventory from receiving to shipping, and enhancing overall operational flow.

Managing the vast amounts of data generated by warehouse operations requires proper analytical tools. A robust WMS analyzes this data, providing insights that drive better decision-making and operational efficiency.

Automation and Robotics

The integration of automation and robotics in warehouses has revolutionized warehouse operations, enhancing efficiency to maximize efficiency and reducing manual labor requirements. Automated systems like AS/RS and autonomous mobile robots play a key role in modern warehouse operations, improving efficiency and accuracy.

Collaborative robots take on repetitive tasks, allowing human workers to focus on more complex duties.

Tips for Hiring the Right Warehouse Manager

Hiring the right warehouse manager can significantly enhance team dynamics and operational efficiency. Identifying candidates with prior leadership experience and the ability to set and achieve targets is crucial. Discuss the candidate’s management philosophies and teamwork preferences to assess cultural fit during the hiring process. This helps ensure that the new manager will integrate well with the existing team and organizational culture.

Additionally, look for candidates who demonstrate strong problem-solving skills, effective communication, and the ability to motivate and manage staff. These qualities are crucial for maintaining a cohesive and high-performing warehouse team.

Common Challenges Faced by Warehouse Managers

Warehouse managers face a myriad of challenges, from inventory shortages to labor management. Managers with effective problem-solving skills can quickly address issues like equipment failures and inventory discrepancies, ensuring smooth operations. Other challenges such as orders from multiple sales channels can complicate fulfillment and increase the likelihood of errors.

Labor management is another significant challenge, as it often consumes up to 65% of a warehouse’s total budget. The rise of ecommerce has driven increased adoption of automation technologies to meet rapid fulfillment demands. However, many warehouses still rely on outdated manual processes, which can slow down operations and increase costs. Warehouse managers must stay on top of all of this and more to maintain an efficient operation.

Career Growth Opportunities for Warehouse Managers

Warehouse managers have ample opportunities for career advancement. They can move up to senior positions such as logistics director or operations manager, overseeing more extensive supply chain functions. Experience in warehousing or logistics management, combined with formal education, is highly valued and can facilitate career progression.

Networking and gaining experience in various warehouse operations and distribution operations open doors to upper management roles in transport companies. Continuous education and training in supply chain management are encouraged for those seeking to advance their careers.

Cadre Technologies’ Warehouse Management Solutions

As warehouse managers juggle responsibilities like inventory management, staff coordination, and safety compliance, having the right tools can make all the difference. Cadre Technologies offers advanced warehouse management systems (WMS) designed to streamline these processes. Our software provides real-time visibility into inventory levels, automates routine tasks, and enhances order fulfillment accuracy.

By integrating Cadre’s WMS into your operations, you can reduce manual errors, improve productivity, and maintain the high standards required for today’s fast-paced logistics environments. Whether you’re facing the challenges of fluctuating inventory levels or coordinating complex shipping and receiving processes, Cadre’s solutions are tailored to meet the needs of modern warehouses, helping managers maintain operational excellence and drive growth.

Summary

In summary, a warehouse manager plays a pivotal role in the logistics and supply chain industry. From managing inventory and overseeing staff to implementing safety protocols and leveraging technology, their responsibilities are vast and varied. Utilizing advanced tools like Cadre Technologies’ Warehouse Management Systems can significantly enhance efficiency and accuracy in these critical tasks. By honing essential skills, obtaining the right education and certifications, and leveraging modern technologies, warehouse managers can excel in their roles and advance their careers in this dynamic field.

Ready to take your warehouse operations to the next level? Explore Cadre Technologies’ WMS solutions today, or contact us to learn more about how we can support your specific needs.

Frequently Asked Questions

What are the main responsibilities of a warehouse manager?

A warehouse manager mainly oversees inventory levels, manages staff, implements safety protocols, coordinates logistics, and ensures timely deliveries. It’s all about keeping everything running smoothly and efficiently.

What educational qualifications are required for a warehouse manager position?

To snag a warehouse manager role, having a bachelor’s degree in business, logistics, or something similar is often preferred, but an associate degree with relevant work experience can also do the trick. Applicants should make sure to highlight any hands-on experience they have.

What is the average salary for a warehouse manager?

The average salary for a warehouse manager in the U.S. is around $96,498, but it can vary based on location and the size of the warehouse.

What technologies are commonly used by warehouse managers?

Warehouse managers typically rely on Warehouse Management Systems (WMS) and automation technologies like autonomous mobile robots to boost efficiency and streamline operations. Embracing these tools can make a significant difference in managing warehouse tasks effectively.

What are some common challenges faced by warehouse managers?

Warehouse managers often struggle with inventory shortages, labor management, and handling orders from various sales channels, especially with the increasing demand from ecommerce. It’s essential to find efficient solutions to navigate these challenges successfully.