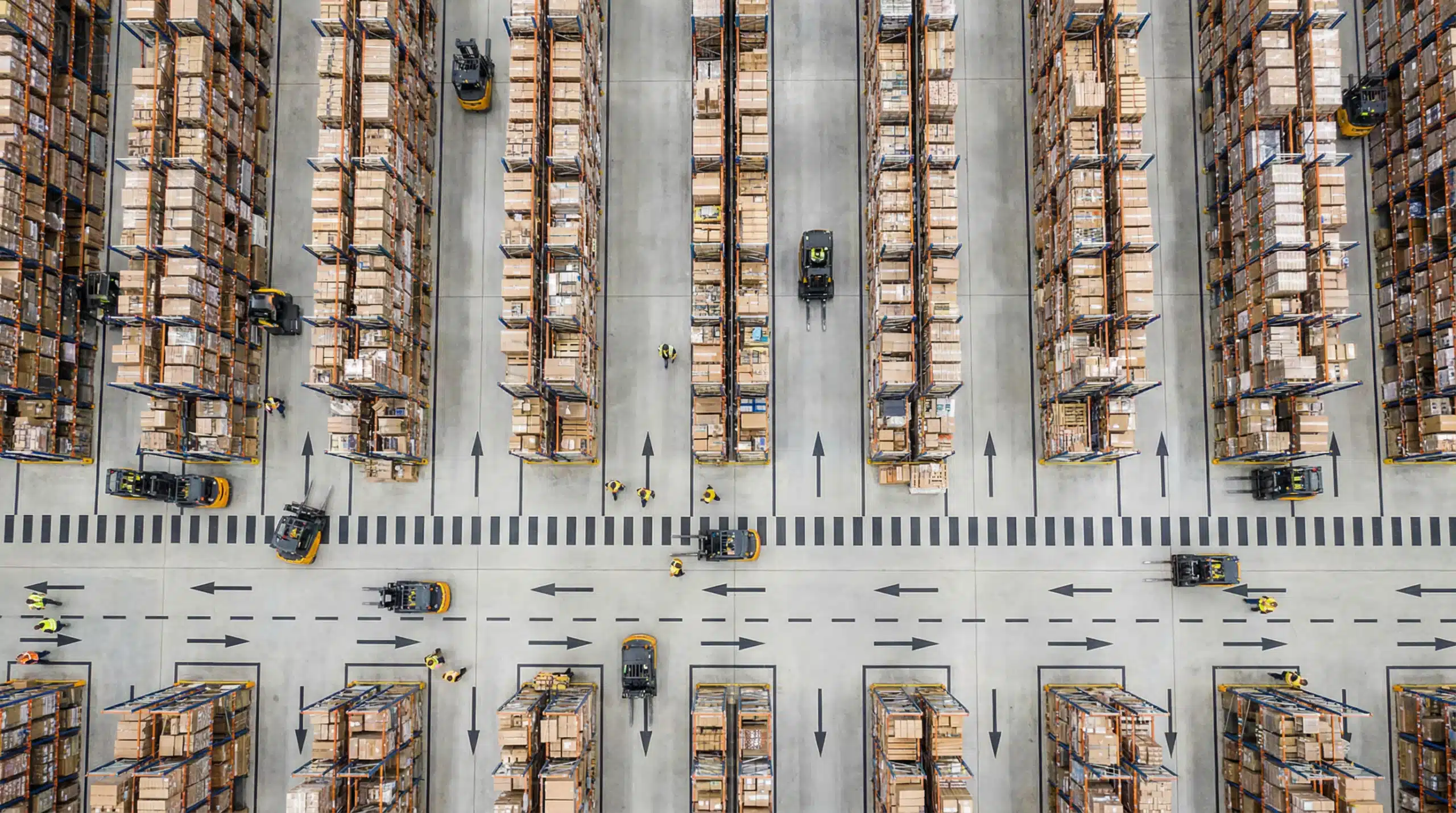

Wave Picking vs Waveless… Which is better for eCommerce?

As eCommerce continues to grow exponentially along with two-day, next-day, and same-day delivery methods becoming the standard; a faster more dynamic way of picking is required. One of the factors that has led to the demand for faster shipping times is the introduction of Amazon Prime. This membership, which offers 2-day shipping for its products, was launched in 2005 and now has over 200 million members.

So, when it comes to picking for eCommerce, is wave picking or waveless picking better? Are there other picking methods that work better?

Wave Picking

Wave picking is a picking method of creating groups of orders (waves) that are released to the warehouse on either a predefined time or manually by the warehouse manager. The waves are a ‘group’ of orders that are related. Examples would be carrier/carrier service (i.e. next day overnight), number of order lines, type of box required, etc. The underlying theme of a wave is predefined by the profile of the orders that make up the wave, making the warehouse picking operation more efficient. Using a system, such as a WMS, waves can be created based on pre-defined rules or they can be manually created and released. Waving is the equivalent of an ‘electronic folding table’ which in the past, was used to sort orders before being given to the warehouse for picking. Other examples of waving: group orders by level of priority, destination, customer, product attributes, etc.

Smarter Warehouse Management Starts Here

Cadre WMS delivers real-time visibility, automated workflows, and seamless ERP integration for warehouses of every size.

Request a Demo

Waveless Picking

Waveless picking is form of “batch picking” where multiple orders can be picked at the same time, but this process is dynamic meaning that new groups of orders can be added.

In a warehouse fulfilling eCommerce orders, a process needs to allow for changes. Meaning if a warehouse worker is picking orders and a new order was just placed for an item along that warehouse workers path, in waveless picking, the system can add that order, so the item is picked along the way. In wave picking, that order would be placed in another wave requiring another lap around the warehouse and delaying when that order would be shipped. So, in a waveless pick, the picking method will determine what is being picked. Picking multiple orders at a time will be the most efficient method as making one pass through the warehouse is more efficient.

So, is waveless picking better? Maybe. Understand the definitions and the relationship to the picking method. Your warehouse might be fulfilling orders that come from a variety of sources, have different shipping deadlines, and have a variety of shipping destinations whether it be to stores, distribution centers, or consumers. So, you can divide up these orders into different picking processes depending on these factors. So, most likely the answer is…both methods co-exist and really depends on the order profile and workflow.

If you would like to know more about different picking methods or about our Warehouse Management Systems, we would love to answer your questions and help come up with a solution that works best for you and your warehouse operations. Contact us today.

Frequently Asked Questions

What types of warehouses benefit most from waveless picking systems?

High-volume eCommerce warehouses with frequent order changes and tight delivery deadlines benefit most from waveless picking. This includes fulfillment centers handling same-day or next-day deliveries, multi-channel retailers, and operations processing orders from multiple sources with varying priorities. Warehouses with consistent product velocity and dynamic order flows see the greatest efficiency gains.

How much does implementing wave or waveless picking technology typically cost?

Implementation costs vary significantly based on warehouse size, existing systems, and chosen WMS provider. Basic wave picking functionality may cost $50,000-$200,000, while advanced waveless systems can range from $100,000-$500,000 or more. Factors include software licensing, hardware upgrades, integration complexity, training, and ongoing support. ROI typically occurs within 12-24 months through improved efficiency.

Can wave picking and waveless picking work together in the same warehouse?

Yes, many warehouses successfully use both methods simultaneously for different order types. Wave picking might handle bulk B2B orders or scheduled shipments, while waveless picking manages urgent eCommerce orders requiring immediate fulfillment. This hybrid approach allows operations to optimize efficiency based on specific order characteristics, shipping deadlines, and customer requirements while maximizing overall warehouse productivity.

What picking accuracy rates can warehouses expect with each method?

Both wave and waveless picking can achieve 99%+ accuracy when properly implemented with barcode scanning and WMS integration. Waveless picking may have slightly higher accuracy due to real-time system updates and dynamic route optimization. However, accuracy depends more on technology integration, worker training, and process design than the picking method itself. Proper implementation of either system significantly improves accuracy over manual methods.

How do seasonal demand spikes affect wave versus waveless picking performance?

Waveless picking typically handles seasonal spikes better due to its dynamic flexibility and real-time order integration. During peak periods like Black Friday, waveless systems can instantly incorporate new orders into existing pick routes. Wave picking may struggle with rapidly changing order volumes and priorities, requiring frequent wave replanning. However, well-planned wave strategies can effectively manage predictable seasonal patterns with proper forecasting.