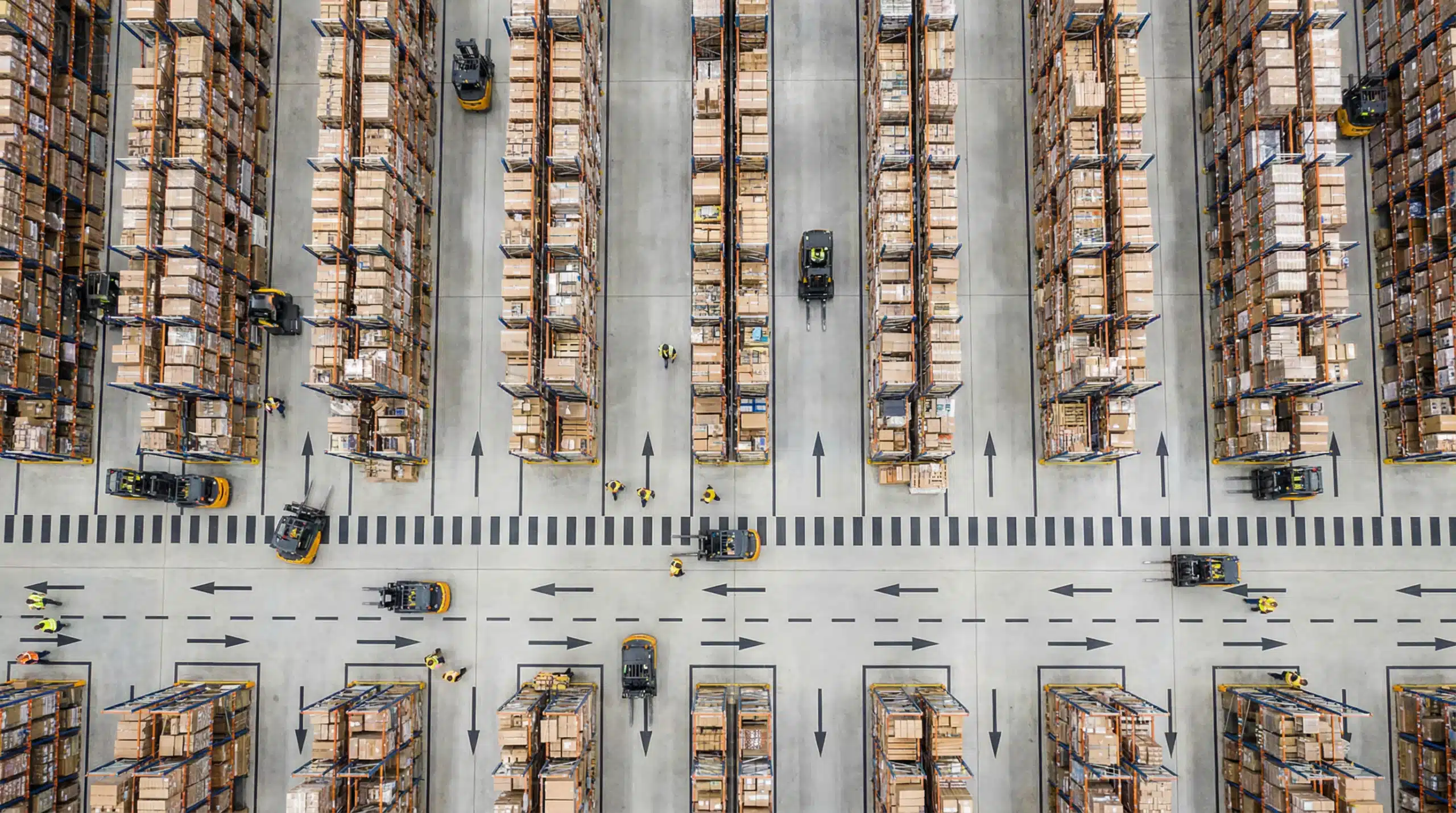

The Role of Visibility in Your Shipper Network

In the rapidly evolving, hyper-competitive world of supply chains, visibility stands as a paramount cornerstone. Creating a visible environment at every stage of your supply chain not only fosters transparency for all stakeholders but also yields manifold benefits you may not have anticipated. Harnessing the right technology is key to achieving this, but understanding why this enhanced visibility matters in such a competitive market is the first step.

Evolving Expectations: Your Partners and Customers Demand Visibility

We inhabit a world where visibility is the norm, not an exception. The current zeitgeist demands real-time information, accessible on screens whether at work or on the go. This burgeoning trend is propelling e-commerce growth, with both retailers and customers placing greater emphasis on transactional transparency.

In this era of immediate information, shippers are not only tasked with faster order fulfillment but also with providing dependable data. This demand emanates from the end-customers, necessitating shippers to collaborate with supply chain operators who can offer enhanced data transparency.

Fueling Efficiency: The Direct Correlation with Visibility

The equation is straightforward: heightened visibility equates to increased efficiency in your supply chain. The reason lies in the power of data analytics. With detailed visibility, you can generate comprehensive reports that highlight any inefficiencies within your operations, providing valuable insights to formulate effective solutions. Visibility acts as a spotlight, illuminating areas of waste and inefficiency across your supply chain. As a result, the efficiency of your processes is significantly enhanced.

Boosting Accuracy: The Beneficial Byproduct of Visibility

Alongside efficiency, visibility also elevates your operational accuracy. By uncovering inefficiencies, you gain insights into issues like driver detention and delays. The elimination of paperwork through digitalization not only reduces errors but also makes critical information such as order and inventory data readily available.

Communication redundancies are a thing of the past, and forecasting of truck demand becomes more precise. The integration of data into a unified system or a ‘control tower’ offers clarity for both you and the shipper, improving accuracy in the critical numbers that keep your operations running smoothly. This increase in precision can help to streamline your operations and improve customer satisfaction.

For instance, our software solution at Cadre Technologies offers real-time visibility that enables higher accuracy and efficiency in managing your shipper network. It provides a seamless, integrated view of your entire operation, making it easier to identify and address any issues or inefficiencies.

Visibility: The Competitive Advantage in Today’s Market

Greater visibility in your shipper network is no longer a luxury; it’s a competitive necessity. Leveraging the right technology can provide this visibility, resulting in improved efficiency, accuracy, and overall operational effectiveness. It’s time to shine a light on your operations and reap the benefits of a more visible supply chain.

Ready to enhance the visibility of your shipper network? Contact us today to learn how Cadre Technologies’ tailored solutions can boost your operational efficiency and accuracy.

Frequently Asked Questions

What specific technologies enable real-time visibility in shipper networks?

Key technologies include GPS tracking systems, IoT sensors, cloud-based platforms, and integrated data management systems. These solutions provide real-time location data, shipment status updates, and centralized dashboards. Transportation management systems (TMS) and electronic logging devices (ELDs) also contribute to comprehensive visibility across the supply chain.

How long does it typically take to implement visibility solutions?

Implementation timelines vary based on network complexity and existing infrastructure, typically ranging from 3-12 months. Simple tracking solutions can be deployed in weeks, while comprehensive integrated systems require several months. The process includes system integration, staff training, and data migration from legacy systems.

What are the main barriers companies face when improving supply chain visibility?

Common obstacles include legacy system integration challenges, data silos across departments, and resistance to change from staff. Budget constraints and concerns about data security also present barriers. Many companies struggle with standardizing data formats across multiple partners and ensuring all stakeholders adopt new visibility tools consistently.

How do you measure the ROI of supply chain visibility investments?

ROI is measured through reduced operational costs, improved on-time delivery rates, and decreased inventory holding costs. Key metrics include reduced detention fees, lower fuel costs from optimized routes, and improved customer satisfaction scores. Most companies see measurable returns within 12-18 months through enhanced efficiency and reduced manual processes.

What data should be prioritized when building a visibility system?

Essential data includes real-time location tracking, delivery timestamps, and inventory levels at key points. Order status, carrier performance metrics, and exception alerts should be prioritized for immediate impact. Temperature and condition monitoring for sensitive goods, along with estimated arrival times, provide comprehensive visibility for effective decision-making.